In order to better understand the performance of CNC bending machine, it is necessary to have a deep understanding of its external organization. This type of product has lost a large number of applications in the control of plate bending machine. By using the numerical control bending machine, the high consumption efficiency and high quality parts can be lost in the processing of simple shape plates, and the high economic benefits can be obtained.

1.1 the performance and operation of the bending machine are important for the upper display press. Its important operation feature is that the vertical downward pressure is composed of two parallel and static operation hydraulic cylinders to drive the last on the bending beam to continue the bending operation. Its numerical control type dipma hydraulic pressure grasps the fine crushing, mainly if grasps the synchronous operation in the bending and the dead point positioning of the hydraulic cylinder when the tool is under full load operation.

The static cycle stage of the model bending process of the upper bending beam is as follows:

(1)static state

The static position of the bending machine is the upper dead center of the upper bending beam. In order to prevent uncontrolled downward stillness, a non leakage back pressure valve is used to open the rod chamber of the hydraulic cylinder.

(2)static downward

In the same way, the common bending machine's fast upward opening and static mostly accepts the content of free landing, that is, the self weight of the bending machine beam and its accessories comes to rest. In this chamber, the rodless chamber of the hydraulic cylinder is filled with oil through a charging valve, at this time, the rodless chamber will have back pressure. If the fast forward progress can reach 250mm / s), it will be controlled by the open-loop or closed-loop valve of the comparison position. After a short braking period, the fast forward stops at a maximum interval of 6mm from the bending plate. All families of opposite bending machines seek opposite fast forward to finish the position.

(3)stamping / bending

The stamping / bending stage is from the end of pressure building of rodless cavity. The stamping schedule is limited by the oil supply quantity of the oil pump, and the other schedule can be adjusted by the position valve of the comparison valve. At the same time, the position valve also grasps the synchronous operation of the bending beam and the positioning of the lower dead center. The limitation of the impulse pressure is accomplished by comparing the pressure of the pump limited by the relief valve. The given values of the corresponding progress, synchronization, positioning and pressure are all from the CNC.

(4)decompression

The decompression of rodless cavity may end when it reaches the lower dead point, or it may end after a short pressure holding time in succession, so that the deformation data will be active when it is certain, so that the dimensional accuracy of the parts can be further improved. The pressure maintaining and pressure reducing are completed by comparing the position valve according to the instructions of the CNC machine. According to the operation cycle, we need to reduce the pressure only in a short time; however, in order to prevent the occurrence of unloading in all the details, we need to find a long dividend. In short, the decompression curve is not allowed to be too steep to waver. All the optimizations are realized by comparing the position valve.

(5)return

The flow of the pump and the pressure bearing area of the rod cavity of the hydraulic cylinder determine the maximum return progress, which is close to the rapid progress in most cases. The return journey from the end of decompression to the end of the upper dead center. The same goes for backhaul.

1.2 CNC bending machine hydraulic control how many kinds of fine content CNC bending machine hydraulic control content, in the production of consumption, to have a high level of initiative and type rate. For this reason, the bending machine should have a high integration rate of integrating hydraulic fine crushing into the tool. As a result, the frame becomes the basis of the assembly of hydraulic parts, through which the oil tank is integrated into the stamping frame. This kind of integration rate is not the same for users who want the opposite from each family.

As usual, there are two styles, as follows:

(1)three master valve block

This type occupies three master valve blocks. Two master-hand valve blocks with inter plate filling valves are indirectly assembled on the hydraulic cylinder. Jiangsu Changzhou Huili CNC Equipment Co., Ltd. mainly produces bending machine, numerical control bending machine, hydraulic bending machine, numerical control shearing machine, electro-hydraulic bending machine, digital display bending machine, etc. numerical control bending machine / hydraulic bending machine has a wide range of types and specifications, and sells well in more than 20 provinces, cities and districts in China. And exported to Europe, America, Southeast Asia, Middle East and other countries and regions, realizing the seamless connection between the master grip and the hydraulic cylinder. The master valve block is mainly composed of a comparison position valve, a reversing valve with position monitoring and a back pressure cartridge assembly. The comparison directional valve plays a key role in the bending machine, which, together with the CNC, determines the static position, progress, synchronous accuracy and positioning accuracy of the upper bending beam. In front of us, the control block series are equipped with a contrast directional valve with an integrated electronic amplifier, which can be indirectly controlled by a numerical controller. The back pressure component (usually composed of reversing valve and two overflow valves) is designed to be leak free according to the depositor's requirements. The oil suction valve shall carefully fill the oil in the rodless chamber in fast forward and drain the large flow oil in the rodless chamber in return. The above two control blocks and three control blocks, pump control block, constitute a complete three control valve block organization. The most important assembly there is a comparison between the relief valve and a maximum pressure stop valve, and the position detection reversing valve as the pilot valve of the charging valve.

The hydraulic pressure of the master block of model 3 is as follows:

Compared with the relief valve, the maximum stamping pressure is set according to the given value of the numerical control device, and the manual relief valve connected with the hook is carefully set of fine pressure insurance, especially aiming at the too high given value from the numerical control device on the pump.

(2)local control block

The type of local control block is to take care of three control valve blocks and one control block. It is important to use in some special organization of the bending machine (such as tool height limited situation).

For the reason of mastering, it is necessary to arrange the trajectory between the master block and the two ram hydraulic cylinders symmetrically, and ensure that the maximum allowable distance between the master block and the two ram hydraulic cylinders (about 3M) is not greater than that between the two hydraulic cylinders, so the local master block should only be arranged at the place of tools. The master block is connected to the hydraulic cylinder through trajectory. In this type of style, the flange type filling valve is adopted, and the indirect assembly depends on the hydraulic cylinder, and there is an oil suction pipe connected with the oil pipe. The compact structure of the filling valve matches the needs of the bending machine with low overall height.

The detailed hydraulic diagram of master valve type in the model place is as follows:

2. Description of dipma hydraulic products of bending machine

2.1 dipma IGP series internal engagement roller pump

The pump accepts radial and axial pressure to make up for the same sound, with low noise and high volume efficiency. The optimized load distribution imagination and special sliding bearing are adopted to make the pump run continuously under low pressure and extend the service life of the pump.

The working pressure is 33mpa, and the peak pressure can reach 34.5mpa. The displacement can be from 3.6 to 251.7 cm3 / rpm. All dimensions and displacement can be arbitrarily combined with each other.

2.2 position detection type solenoid position valve DS * m

DS * m series valve core detection type solenoid position valve is equipped with remote sensor that can point out the position of valve core, especially PNP type sensor with normally closed contact can guide the position of valve core in the original position (solenoid valve power off). Then it can be connected to the CNC channel to identify the status of the position master valve, so as to continue to master the integrated performance. The oil return port (t port) has high pressure resistance, which can reach 100bar in dynamic condition and 50bar in static condition.

2.3 integrated digital comparison position valve and pressure valve

DS * J series valve is a kind of valve core displacement detection direct acting integrated electric control servo comparison position valve. The valve can be used to master the position and progress of the high static characteristic hydraulic execution organization. The opening and flow of the valve can be adjusted continuously and inversely compared with the output reference flag.

Pre * G series comparison pressure valve is a pilot type comparison overflow valve with integrated electronic control, which is commonly used for accurate hydraulic fine crushing pressure, and the pressure can be adjusted in a row, compared with the reference flag. The maximum holding pressure can reach 350bar.

2.4 dxj * series direct acting servo valve and DS * J series servo comparison valve

Dxj * series valve is a four sided slide valve servo valve. The valve is driven by a momentum motor, which has excellent static performance and is not subject to crushing pressure. The position of valve core is reflected by lvtd, forming a closed-loop and fine, thus ensuring a good accuracy and repeatability. The valve has very small power consumption, which is very practical for the closed-loop control of position, progress and pressure. When the power supply is cut off or the reference flag is written as zero, the valve core returns to the middle position actively, and the leakage of the middle position is very small, which has nothing to do with the fine crushing pressure. There are some differences between hydraulic numerical control bending machine and other types of bending machine in terms of its performance and setting equipment. This type of bending machine is a kind of high active cutting tool for sheet metal processing, so the arrangement and performance of its hydraulic components are also different. Jianda company can supply high-performance hydraulic parts to the depositors, and beat the problems encountered at the maximum level. We are committed to building excellent cooperation with suppliers, providing excellent cost-effective CNC bending machine and the best effectiveness for depositors.

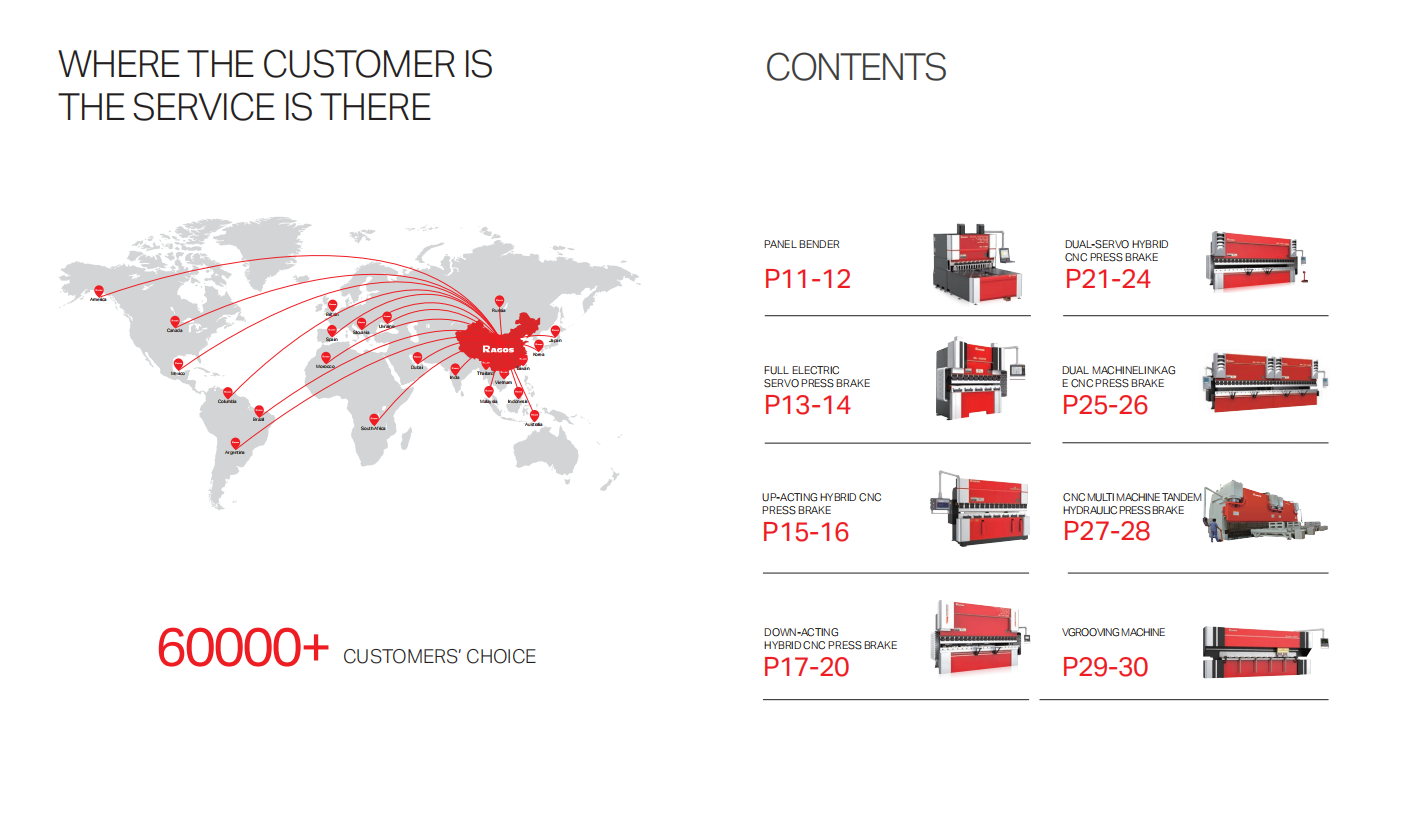

Copyright © 2025 Foshan Ragos NC Equipment co.,LTD. (panel bender) | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via e-mail. Please be sure to leave your contact details so that we can better assist you.